Product Description

2018 Heidelberg Stahl BC/CH Fully Automated Pile Feed Folder

Machine is under power and is being sold with the following accessories

Fully Automated folder with right angle

- Fast setup thanks to simplified operation and automation options

- Wide range of applications thanks to modular machine concept

- Proven HEIDELBERG Stahlfolder technology ensures top folding quality at low operating and investment costs

- Efficient production of short and long runs

- Full compatibility with your existing Stahlfolder equipment

Modular control system MCT for easy operation of your folding machine

The graphical user interface makes the operation easy. With Touchscreen and QuickSetup all necessary settings are done with just four clicks.

The MCT control system consists of a central control panel at the feeder of the folding machine and integrated control functions, both in the following units as well as in the delivery which offer complete control over the most important machine functions. In the learning mode the sheet length is measured and the suction cycle length and sheet gap are automatically set and continuously monitored.

- Machine operation: The user interface of the control panel works with self-explanatory symbols which are clear and explicit regarding function and operation.

- Central Touchscreen: Automated Stahlfolder BH/CH folding machines are equipped with a central touchscreen. The graphical user interface with intuitive symbols makes the operation of the machine extremely simple. A setup assistant leads the operator through the setting process step by step. The most common fold programs can easily be selected from an integrated fold type catalogue. The folding machine can be set with data from the workflow as well.

- The operating mode QuickSetup reduces the range of the control system to the most important settings. Only the sheet format, grammage and fold type must be selected to setup the folding machine. This way you do not only avoid setup errors but your folder is ready for production with only four clicks.

Buckle plate folding units: Precise fold accuracy and short setup times

The Stahlfolder BH buckle plate folders offer maximum flexibility for most different folding applications. The single folding units are mobile and can be positioned depending on the fold type. Thanks to the uniform MCT control system of Heidelberg a Stahlfolder BH configuration can also be combined with other Stahlfolder components like modern delivery systems or a mobile knife fold unit.

- Folding roller drive: The external folding roller drive is equipped with hardened and helically toothed gears, thus providing an extremely precise and nonslip transportation of sheets. The fold quality remains continuously high during the complete production run.

- Manual or motor-driven adjustment of folding rollers: the setting of the folding roller gaps is available either manually with the proven FESTA settings or motorized.

Cross-fold unit: Optimal capacity on little space

- Cross-fold configurations: The Stahlfolder CH machines are available in the cross-fold variants KL, KTL or – with a working width of 78 centimeters - also as KLL or KTLL version.

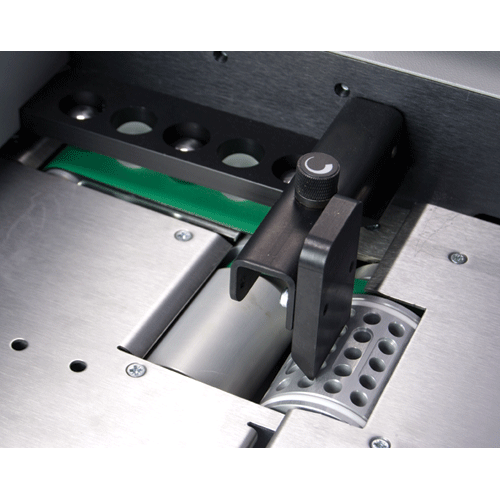

- Folding knife: The folding knife is released by a light sensor which is activated by the trailing sheet edge, thus avoiding misfolded sheets in the delivery. The reinforced knife version ensures a long service life and constantly high fold quality. The segmentation of the first folding knife even allows for a processing of small formats with minimum sheet gap.

- Ergonomic operation: The cross-fold unit is equipped with a central control panel which is mounted on a swivel arm. It allows for an easy operation and good accessibility to all adjustable parts in the cross-fold unit.

Cross-fold unit KT in working width 56

The cross-fold unit of the Stahlfolder CH 56 KT auto with motor-driven buckle plate after the folding knife is completely automated – the first time in format range 50 × 70 cm. After entering the job data at the touchscreen all necessary parameters take their positions in a motorized way, both in parallel and in cross-fold section. This reduces your setup times. In larger circulations you score with the constant high output of the Stahlfolder CH 56 KT auto. This makes you very successful also with a hybrid job structure consisting of small runs from digital presses and larger circulations from conventional offset presses.

Certified Installation and Training Available.