Product Description

These are new paper cutters coming with one year warranty.

Adolf Mohr Maschinenfabrik was founded in 1906 and a few years later started marketing its products under the brand name POLAR and MOHR.

In 1946 Karl and Rudolf, sons of the company founder Adolf Mohr, started specializing in the construction of cutting machines for the paper processing industry. The efficiency, quality and durability of the cutters meant that they were soon regarded as prime examples of the high standard of products "made in Germany", and the company evolved from a regional provider to the world's largest supplier of high-speed cutters.

MOHR cutting machines (in the graphics industry also known as guillotine or paper cutter) are the durable, programmable cutting machines with hydraulic drive units.

Both, the company and the operator value not only the uncomplicated operation, but also the long service life of the cutting machine. The unique cutting precision is obtained by the sturdy construction and the direct measurement.

MOHR 66 (26") ECO:

The machine is operated via an ergonomically arranged control panel with 5.5" monochrome display and extra low-profile keyboard. Repeat sequences can be saved in one of 198 available memory positions and even be adapted at any time.

MOHR 66 (26") PLUS:

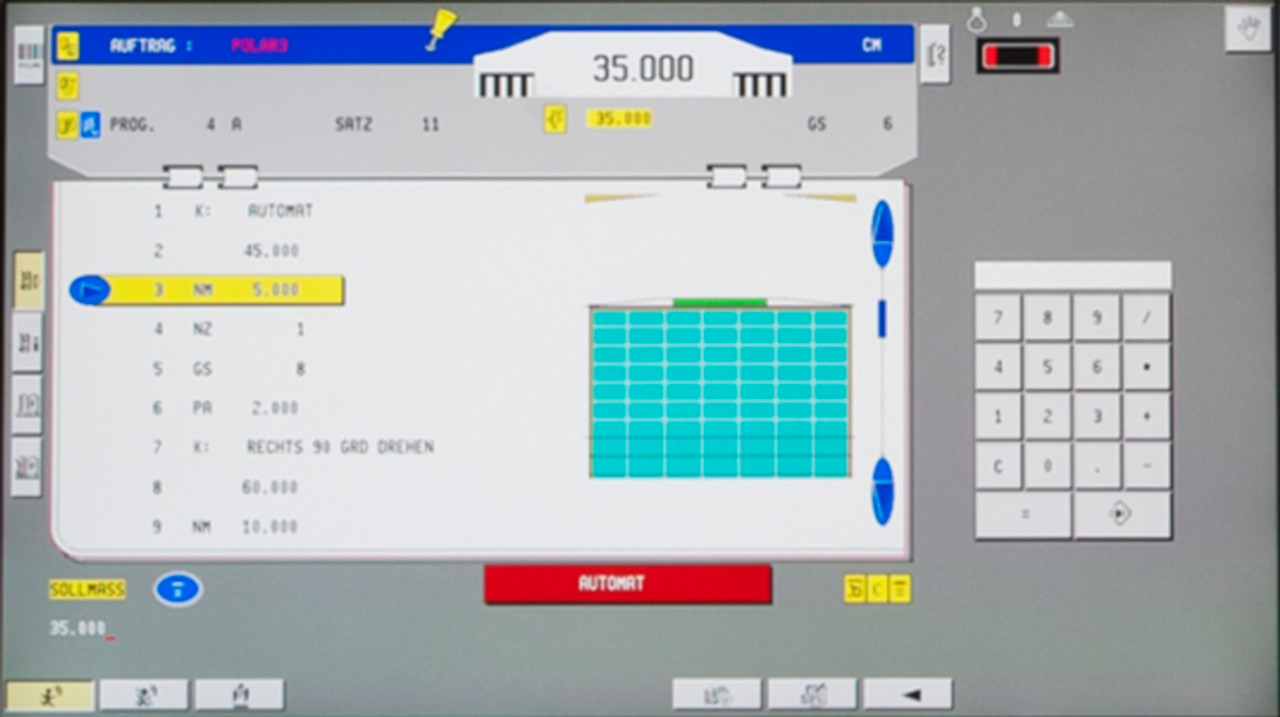

Operation via 18.5" touch-screen display. There are 1998 memory positions available for repeat cut sequences. Due to digital workflow integration Compucut® takes the cutting data supplied as ppf or jdf files direct from the prepress stage.

To automatically start available stored cutting programs, the machine is furnished with a bar-code reader. This allows setup times to be reduced to almost zero. The process visualization gives the operator a graphic indication of the material handling. This minimizes the proneness to errors considerably.

Cutter MOHR 66 (26") ECO

Sturdy, programmable cutter with hydraulic drive and 5,5“ monochrome display.

Customer benefits

• Extensive programming options with a memory capacity of 198 programs

• Easy knife change with automatic interruption in the lower dead end and knife fine adjustment from the front

• Machine frame with optimized stability for optimum absorption of cutting forces and greatest cutting accuracy

• Minimal maintenance requirements due to the use of novel materials

Description of the machine

The cutter MOHR 66 is designed for one-shift operation. The precise and gentle swing cut is carried out hydraulically. Thus, the time of the knife spent in the lower dead end can be adapted to the material. The ultra-smooth stainless table surface allows an easy handling of the material even without air jets. Within a wide setting range the clamping pressure can be adjusted infinitely to each cutting material by means of a turning knob with scale. Bright LEDs mark the cutting line clearly visible for the operator. The operation of the machine is done via an ergonomically positioned control panel with 5.5’’ monochrome display and additional membrane keypad. Recurring cutting sequences can be memorized (memory capacity 198 programs) and adapted at any time. The creation of the cutting programs is done either manually or menu-driven and intuitively via block programming. To optimize the cutting quality the pre-clamping time can be adjusted according to the material.

Technical data

Cutting width 670 mm | 26.38 in

Feeding depth 670 mm | 26.38 in

Feeding height max. 80 mm| 3.15 in

Clamp pressure min. 180 daN | 397 lbs

Clamp pressure max. 1,500 daN | 3,307 lbs

Backgauge speed on return way (0 - ...) 70 mm/sec | 2.76 in/sec

Smallest cut, automatically, without false plate 15 mm | 0.59 in

Smallest cut, automatically, with false plate 50 mm | 1.97 in

Dimensions (w × d × h) 1,250 × 1,825 × 1,500 mm | 49.21 × 71.85 × 59.06 in

Weight 675 kg | 1,488 lbs

Cutter MOHR 66 (26") PLUS

Sturdy, programmable cutter for integration into the digital workflow with 18.5” touch-screen display, barcode reader, Compucut® and process visualization.

Customer benefits

• Barcode reader for automatic cutting program creation and loading of the assigned program via Compucut®

• Process visualization for the graphical display of the material handling to minimize the risk of errors

• Machine frame with optimized stability for optimum absorption of cutting forces and greatest cutting accuracy

• Minimal maintenance requirements due to the use of novel materials

Description of the machine

The cutter MOHR 66 is designed for one-shift operation. The precise and gentle swing cut is carried out hydraulically. Thus, the time of the knife spent in the lower dead end can be adapted to the material. The ultra-smooth stainless table surface allows an easy handling of the material even without air jets. Within a wide setting range the clamping pressure can be adjusted infinitely to each cutting material by means of a turning knob with scale. Bright LEDs mark the cutting line clearly visible for the operator.

The operation of the machine is done via an ergonomically positioned 18.5’’ touch-screen display. Recurring cutting sequences can be memorized (memory capacity 1,998 programs) and adapted at any time. Integrated in the digital workflow the cutting data is taken over directly from pre-press into Compucut® as ppf- or jdf-file. Then Compucut® generates automatically the cutting program. To start the cutting program automatically the machine is equipped with a barcode reader. Hence, the set-up time can be reduced to nearly zero. With the process visualization the handling of the material is displayed graphically and so the risk of errors significantly downsized. To optimize the cutting quality the pre-clamping time can be adjusted according to the material.

Technical data

Cutting width 670 mm | 26.38 in

Feeding depth 670 mm | 26.38 in

Feeding height max. 80 mm| 3.15 in

Clamp pressure min. 180 daN | 397 lbs

Clamp pressure max. 1,500 daN | 3,307 lbs

Backgauge speed on return way (0 - ...) 70 mm/sec | 2.76 in/sec

Smallest cut, automatically, without false plate 15 mm | 0.59 in

Smallest cut, automatically, with false plate 50 mm | 1.97 in

Dimensions (w × d × h) 1,250 × 1,825 × 1,500 mm | 49.21 × 71.85 × 59.06 in

Weight 675 kg | 1,488 lbs

Certified Installation and Training Available